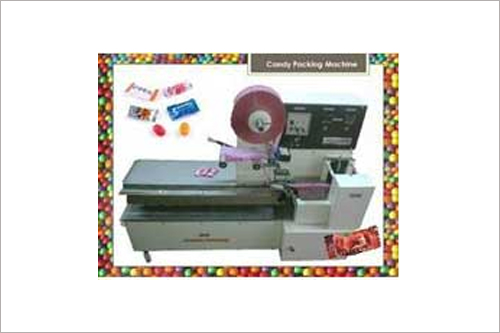

Tabletop Candy Wrapping Machine

Cut and twist wrapping machine features.

Tabletop candy wrapping machine. Get it as soon as thu oct 8. Full speed control via an electronic inverter. The ttdf offers opportunities to replace hand wrapping of baked goods candy bars and other low volume products for growing businesses. So if the multiple products are all the same size the ttdf can wrap them.

It is fitted with a photocell for print registration. What are the minimum product dimensions for the ttdf. The sealing goes on the bottom. If they are different sizes then you need a machine for each size.

With the ability to vend 14 snacks candy and food selections this machine is perfect for pastries chips crackers and healthy vending food products with a total capacity of 150 items. Honor pack confectionery packaging solutions extend packaging wrapped candies by weight fill seal into big pouches by vffs rfs and load pouches into carton. Our low price guarantee means you get the absolute best tabletop candy machine on the market for the best price guaranteed. The loynds cut twist wrapping machine will cut and wrap up to 500 pieces per minute.

Includes two 8 dry cases display tables candy making area including 9 three compartment sink hand sinks washer dryer granite candy table ss prep table 3 hilliards temp machines 1 100 lb hilliards melter enrober true ss split door fridge and matching true freezer candy chill cabinet approx 25 000 chocolate molds for every. It can produce and wrap squares oblongs cubes and log shaped pieces and it will wrap them in a double twist wrap style. For small items and individual wrapping for candies and other small items the ttdf is an entry level wrapper that offers a simple easy to use inexpensive wrapping process. 1 16 of over 5 000 results for candy wrapping machine foilman twisting wax paper 300 pack best for wrapping homemade candies taffy chocolate fold easily holds the twist shape biodegradable opaque 4 5 x 5 5 4 7 out of 5 stars 67.

Candy wrapper for my nephews honey carmel company bees brothers. As a small batch confectioner who uses her home kitchen erin requires a machine that is low cost compact enough. Erin james a caramel candy proprietor and sponsor of this project has requested the design and build of a machine that will allow her to reduce the amount of time spent cutting and wrapping homemade caramels as this process currently takes too long to be commercially competitive.