Roof Valley Flashing Overlap

Slip a piece of sheet metal flashing under the top layer of shingles to protect the bottom layer in the valley while you cut the shingles with a hook blade.

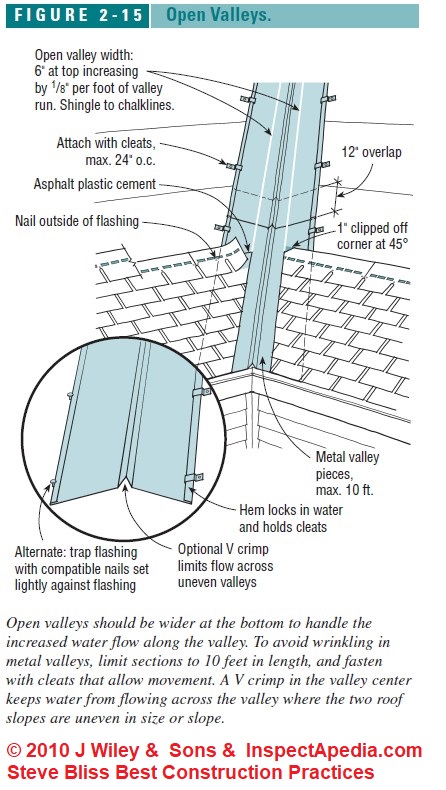

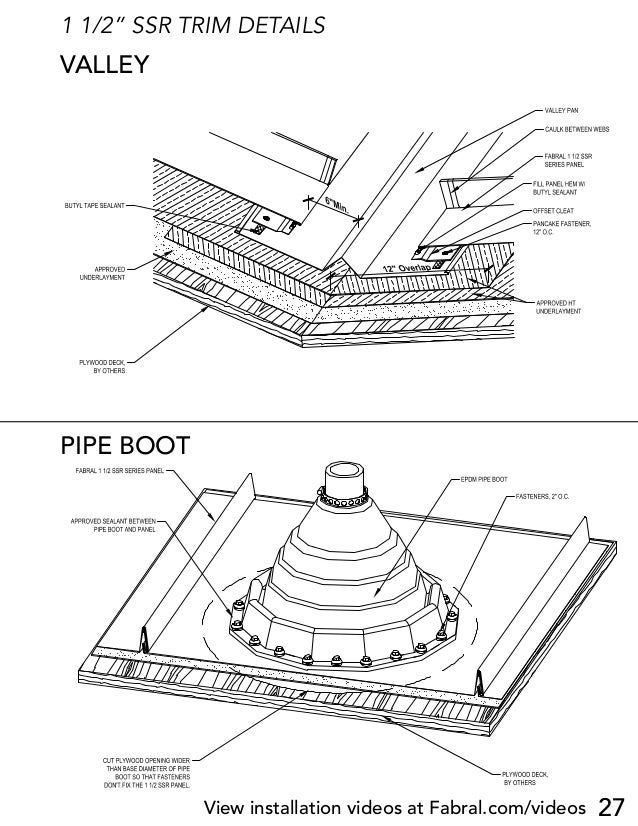

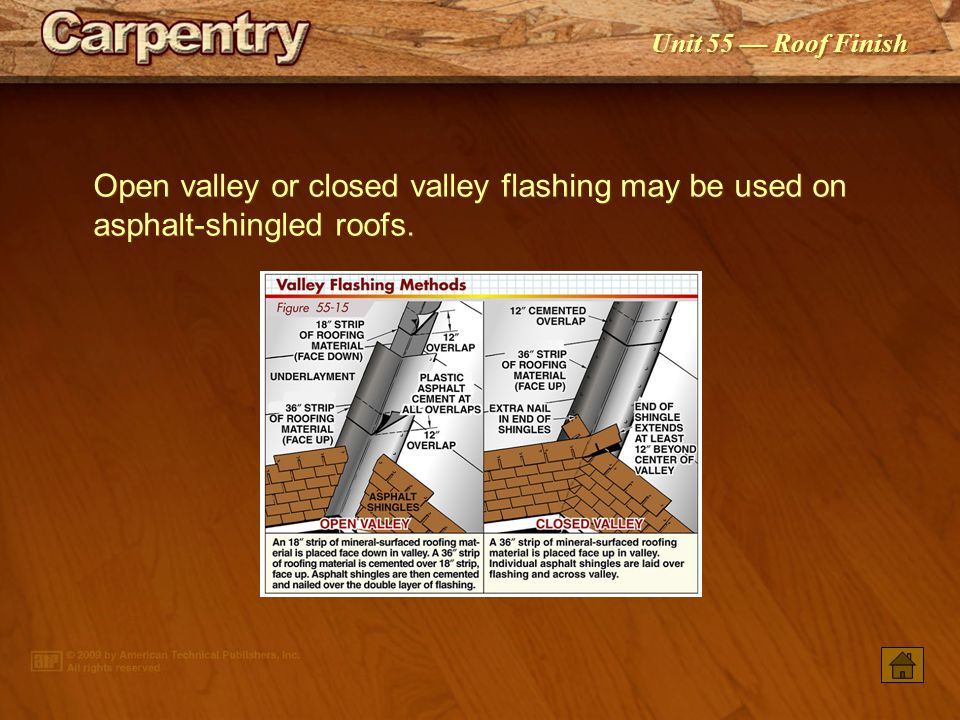

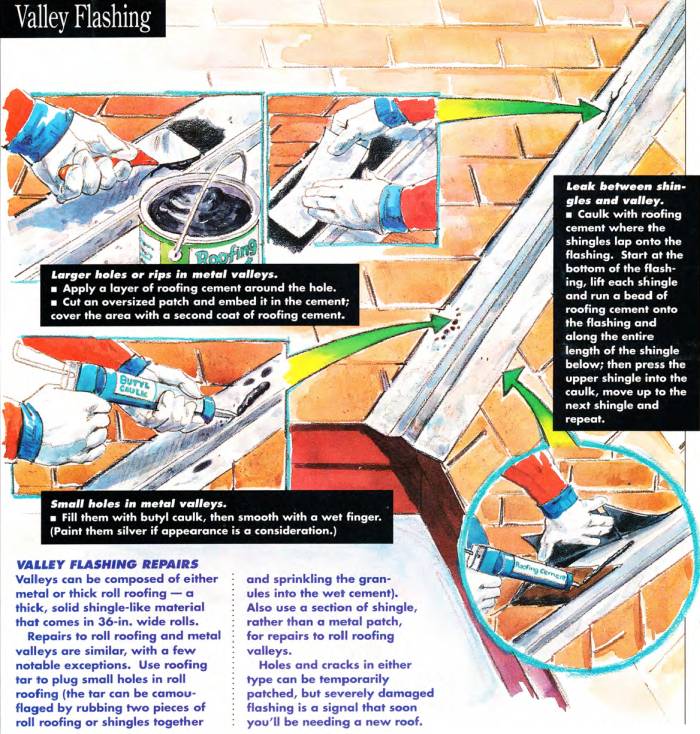

Roof valley flashing overlap. Seal each shingle to the liner and overlapping shingle with a 3 inch wide bead of plastic roofing cement. Laps should comply with the following criteria. Properly sized and installed valley flashing is key to channeling water safely off the roof. Moving up the valley install any additional roof flashing as required to cover the entire length.

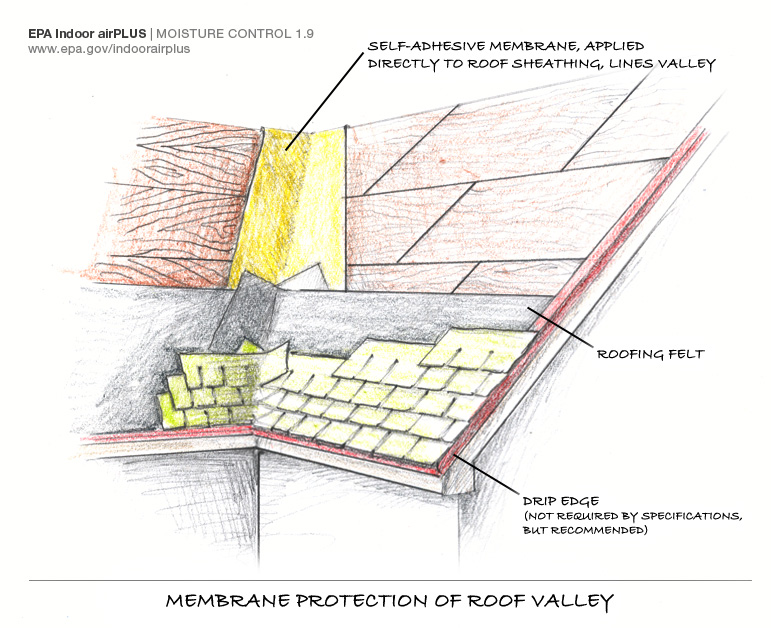

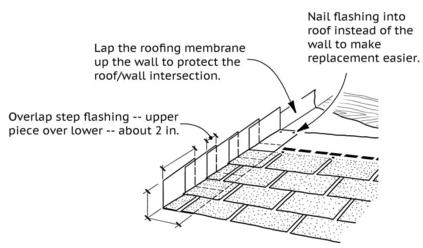

Valley flashing is metal or sometimes peel and stick material that protects an important area on the roof where two slopes come together to form a valley. An overlap must run over not under. Cut the top layer of shingles along the chalkline. Now nail this first flashing at both its far ends.

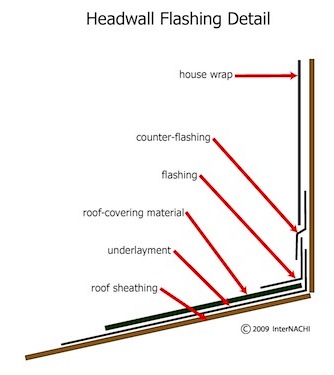

A lap is the part of a flashing that covers or overlaps any part of the similarly shaped component and these can be described as an end lap overlap or underlap. At the end of the vertical sidewall the step flashing shall be turned out in a manner that directs water away from the wall and onto the roof and or gutter. To splice the pieces add roofing cement to the lower piece and install the upper piece with at least a six inch overlap. First apply asphalt plastic cement under the overlap area then place and nail down the second piece of flashing.

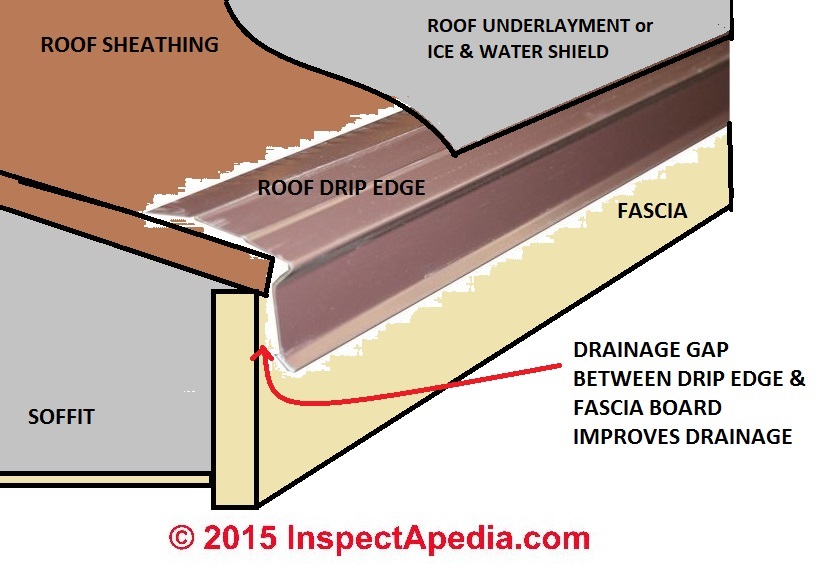

Remember to caulk the underside of the flashing with a sealant. Cut bottom of flashing so the entire width of the valley flashing extends approximately 1 2 to 3 4 over the fascia trim board along eaves the following photos illustrate removal and replacement of a closed cut valley with new open metal valley. Step 9 cut corners and apply cement. Installing drip edge on a humpy old roof dealing with dips and making clean overlaps metal drip edge flashing is installed on the perimeter of a roof to direct water away from the fascia into the gutters and to keep wind blown rain videos roofing wrb flashing drip edge installation on an existing roof.

Overlap each piece of flashing by at least 6 inches 150 mm. Extend entire width of flashing completely to the bottom of the roof valley. Step 6 install the flashing. With a roll roofing valley keep the nails at least 6 inches from the valley centerline.

The flashing shall be a minimum of 4 inches 102 mm high and 4 inches 102 mm wide. With a metal liner nail 1 2 inch outside the liner. Install valley battens on both ends of the roof valley then attach first flashing 3 4 inches over the roof flange and another 3 4 inches over the fascia if any is present. An overlap must run downhill the direction of the water flow.