Roof Sheathing Thickness Ohio

That will suffice on a roof with rafters set 16 inches apart with minimal roof loads.

Roof sheathing thickness ohio. 1 inch 25 4 mm. That s considered to be the minimum. Floor or roof sheathing conforming with this table shall be deemed to meet the design criteria of section 2304 7. Sheathing should be a minimum of 19 32 inch thick.

Loads will vary with the. This minimum will only work if the rafters are set 16 inches apart at most and if the roof doesn t have too much load. The typical thickness range for sheathing is 3 8 to 3 4 inch. Does anyone know what is the current ohio residential code is for roof decking.

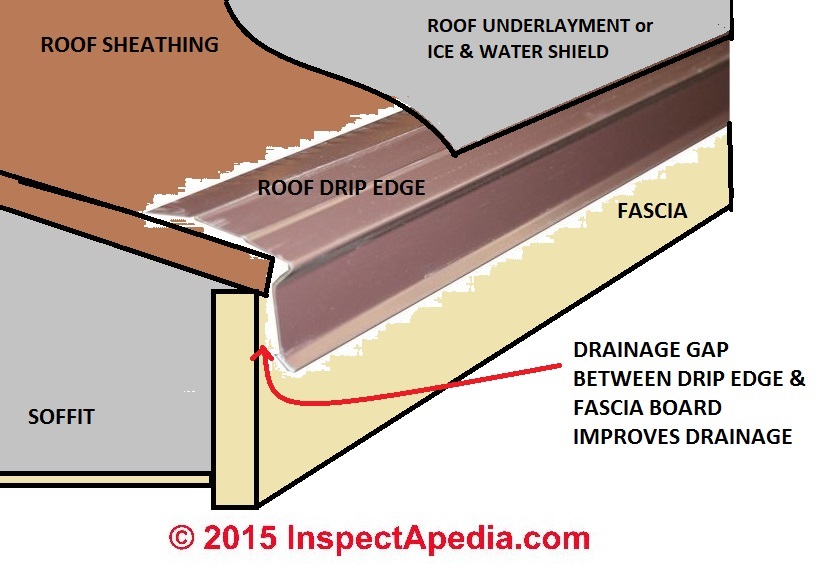

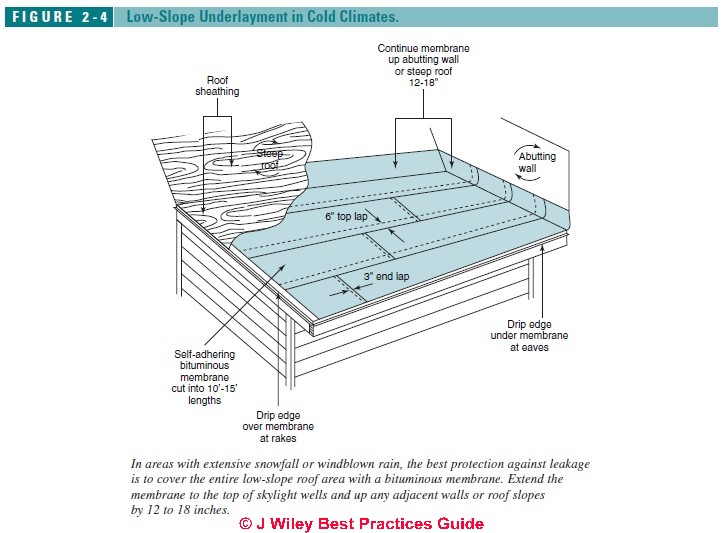

Allowable spans for lumber floor and roof sheathing a b for si. Never attach roof sheathing with staples. Underlayment shall be applied in accordance with section 1507 2 8 except all laps shall be a minimum of 4 inches 102 mm. Where the roof sheathing is less than 3 4 inch 19 1 mm thick the fasteners shall penetrate through the sheathing.

Hip and valley rafters shall be not less than 2 inches 51 mm nominal in thickness and not less in depth than the cut end of the rafter. Fasteners for asphalt shingles shall be galvanized steel stainless steel aluminum or copper roofing nails minimum 12 gage 0 105 inch 3 mm shank with a minimum 3 8 inch diameter 9 5 mm head complying with astm f1667 of a length to penetrate through the roofing materials and not less than 3 4 inch 19 1 mm into the roof sheathing. Roof sheathing thickness unlike with plywood siding the plywood sheet to be used for sheathing should be at least 3 8 inch thick. Underlayment shall be attached using metal or plastic cap nails with a head diameter of not less than 1 inch 25 mm with a thickness of at least 32 gage 0 0134 inch 0 34 mm sheet metal.

This is for a re roof of a shed style roof of a garage with 2x6 rafters not trusses. I am trying to find out the decking thickness for 24oc. Rafters shall be nailed to the top wall plates in accordance with table 602 3 1 unless the roof assembly is required to comply with the uplift requirements of section 802 11. Where flashing is of metal the metal shall be corrosion resistant with a thickness of not less than 0 019 inch 0 483 mm no.

802 4 3 hips and valleys. I was told that the spring of 2008 it changed. Wall and roof intersections at gutters wherever there is a change in roof slope or direction and around roof openings. Installation details shall conform to sections 2304 7 1 and 2304 7 2 for floor and roof sheathing respectively.