Roof Safety Mesh Regulations

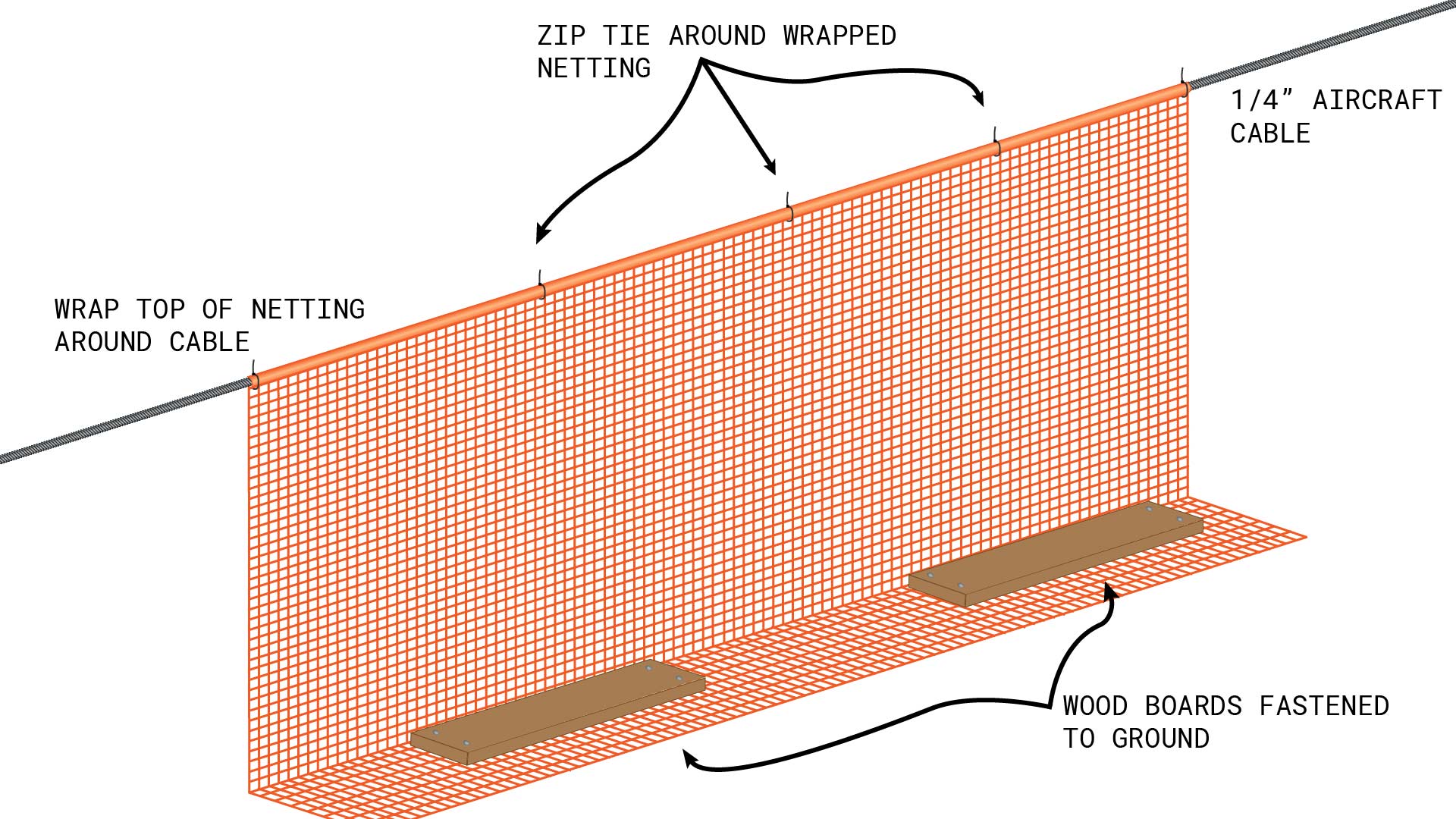

The warning line system shall consist of ropes wires or chains and supporting stanchions 29 cfr 1926 502 f 2.

Roof safety mesh regulations. 3 3 joints connections between rolls or sections of roof safety mesh. 3 2 fixing connections between the roof safety mesh and the roof member. All mesh crossings shall be secured to prevent enlargement of the mesh opening. 9 2 position of roof safety mesh roof safety mesh shall be positioned in accordance with the following.

3 4 lapping where the sides of roof safety mesh are overlayed to prevent a gap forming between the two. Appropriate lifting technique for long roof conforms to as nzs 4389 2015 roof safety mesh is installed by a competent person in a safe manner and in accordance with the manufacturer s instructions has its integrity inspected by a competent person prior to roof maintenance or removal. 9 installation requirements 9 1 general the installation of roof safety mesh shall comply with the requirements of clauses 9 2 and 9 3. Safety mesh has been tested and designed to meet testing standards developed by a national testing authority.

Longitudinal wire must face down with the cross wires facing up all longitudinal wires need to be wrapped around or through drilled holes in the purlins and tied off with a minimum of. All mesh is to be lapped minimum of 150mm one square for purlins 2200 or greater to be lapped. A position of mesh where roof safety mesh is required it shall be fitted under the roof sheeting so that it is supported by metal and or timber purlins rafters or roof members that are part of the roof structure. A ring fastener or hog ring used for joining side laps of roof safety mesh.

The safety monitor is always a competent person 29 cfr 1926 500 b.